Developing a Control and Monitoring System for AGVs — From Thesis to Real-World Application

When I started working on my Bachelor’s thesis, I wanted to do more than just create a concept on paper. I wanted to build something real that could solve an actual problem. The result was a complete control and monitoring system for Automated Guided Vehicles (AGVs), combining hardware, software and user experience design. Today, this system isn’t just a project from my student days. It’s being used by real customers in real production environments.

The Challenge: Making AGVs Easy to Manage

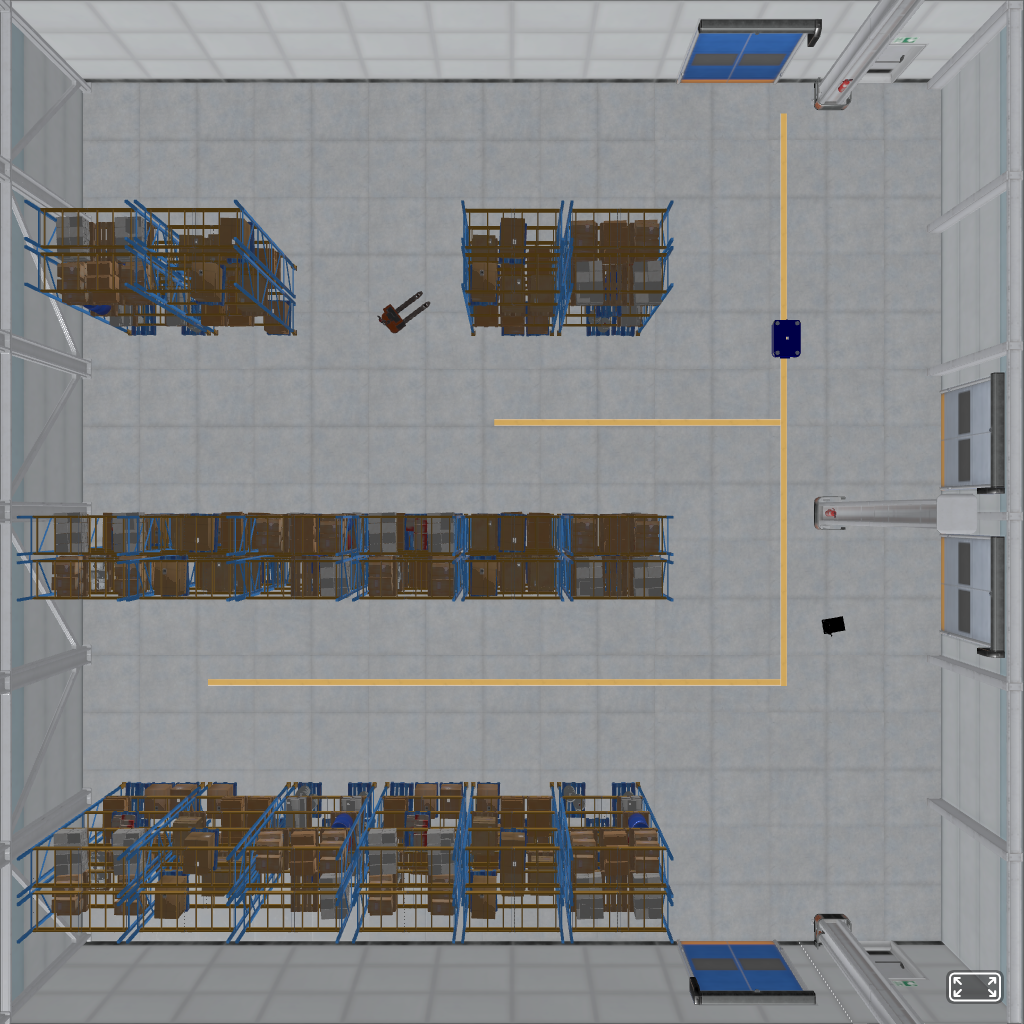

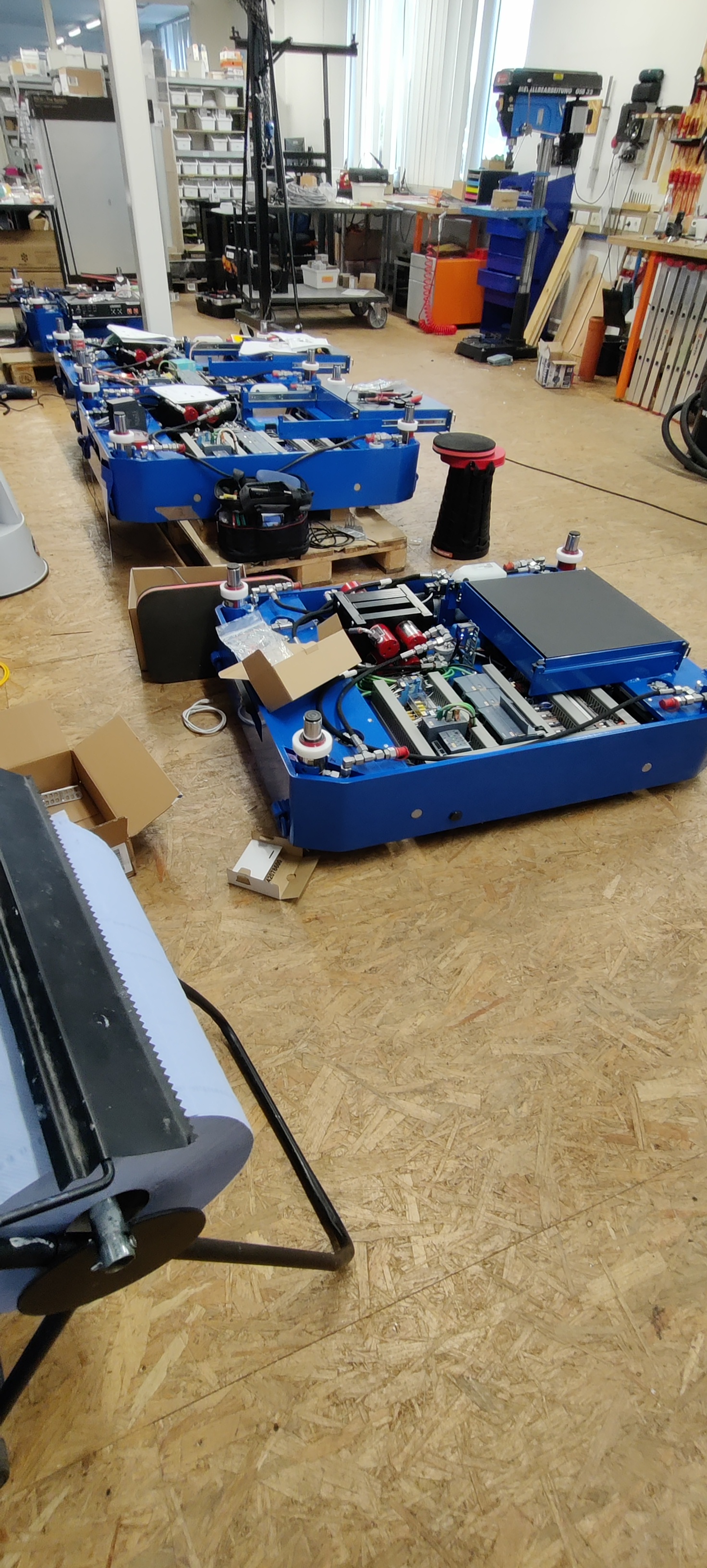

AGVs operating in a production warehouse environment

AGVs operating in a production warehouse environment

AGVs are widely used in logistics and production halls to automate material transport. However, many existing control systems are either too complex, too technical for non-specialists or simply outdated. The goal of my thesis was clear: build a system that made operating and monitoring AGVs as simple and reliable as possible while still offering all the flexibility needed in a dynamic environment.

From Concept to Prototype

Initial Planning and Research

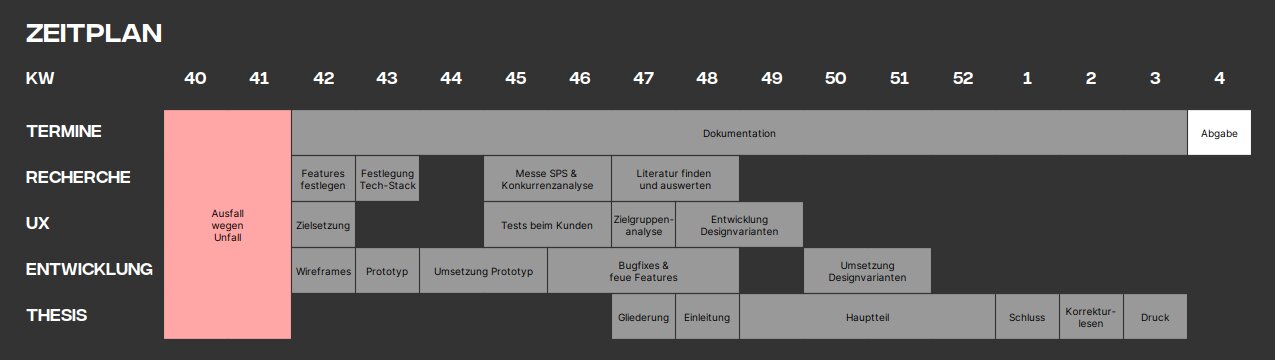

Development timeline and milestones

Development timeline and milestones

User-Centered Design

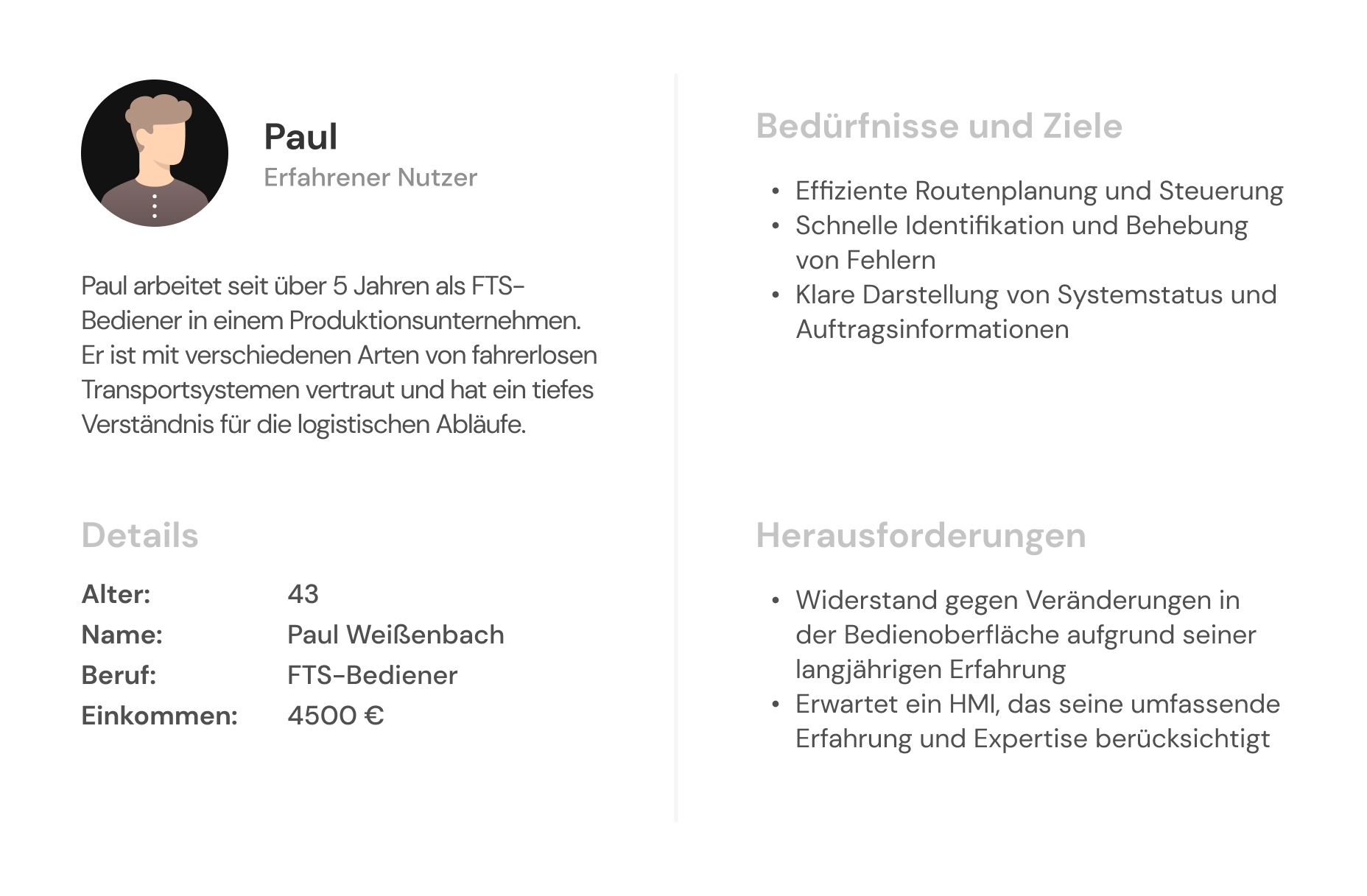

Persona: Paul - Workshop Manager needing simple AGV control

Persona: Paul - Workshop Manager needing simple AGV control

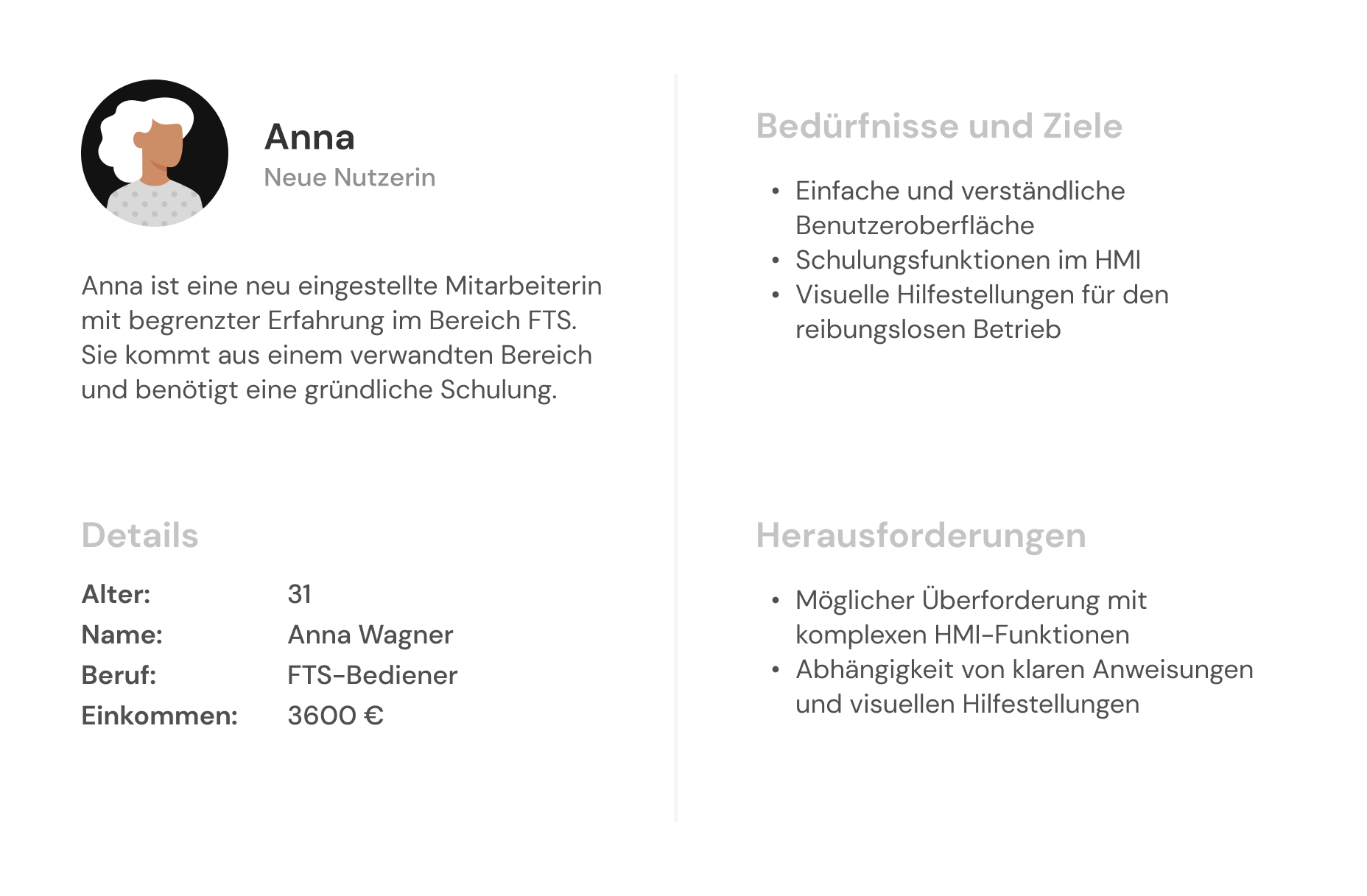

Persona: Anna - Logistics Coordinator monitoring fleet operations

Persona: Anna - Logistics Coordinator monitoring fleet operations

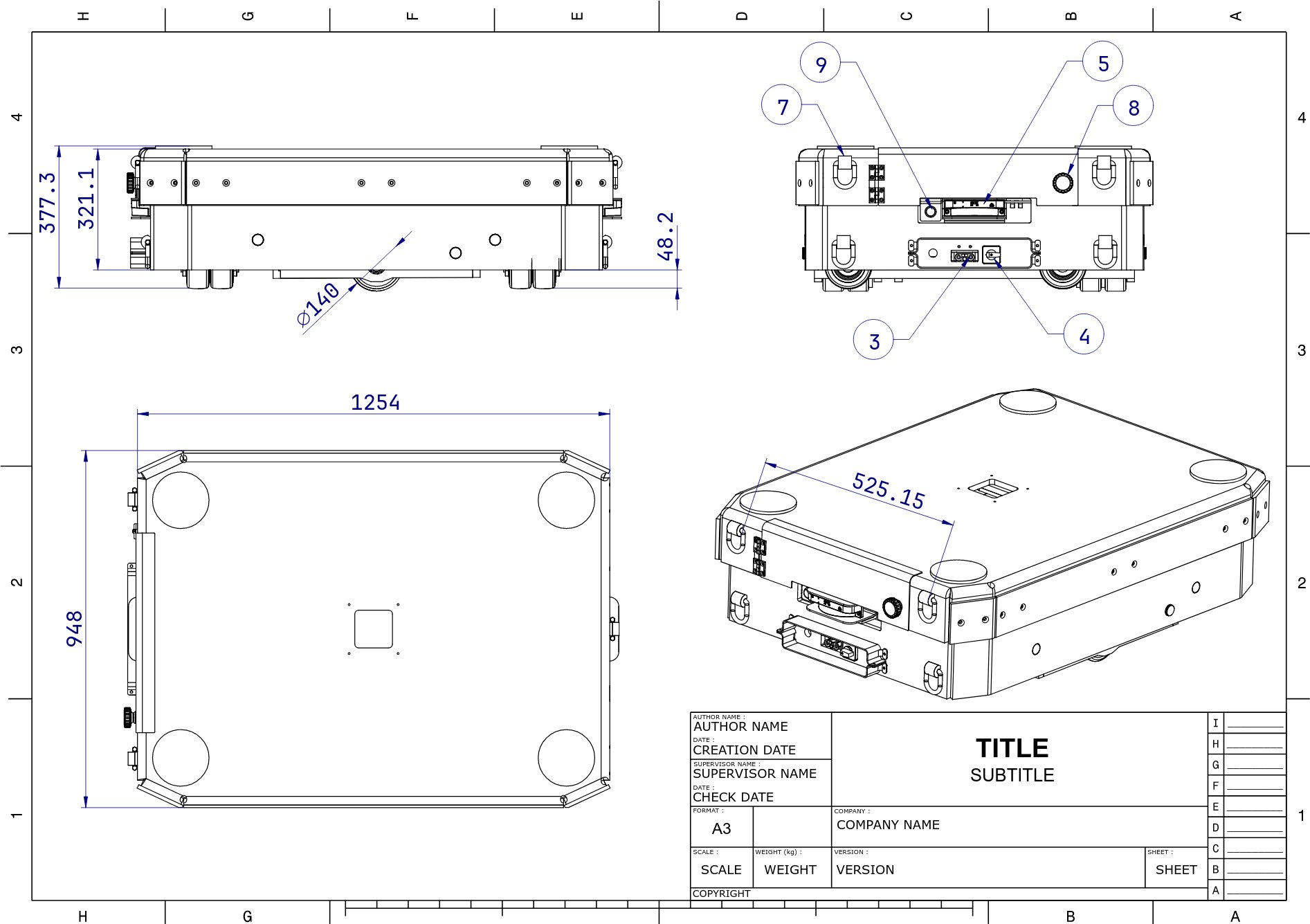

Physical Prototype Development

Testing the console in actual workshop conditions

Testing the console in actual workshop conditions

To turn the idea into reality, I started by designing a physical prototype console. The setup was straightforward but built for industrial needs:

- A rugged wooden frame that could withstand workshop conditions

- An integrated touch-screen PC to run the interface

- Local networking hardware to connect directly to AGVs

The physical build was important not just for presentation, but for real-world testing and user feedback during the development process.

Technology Behind the System

System Architecture

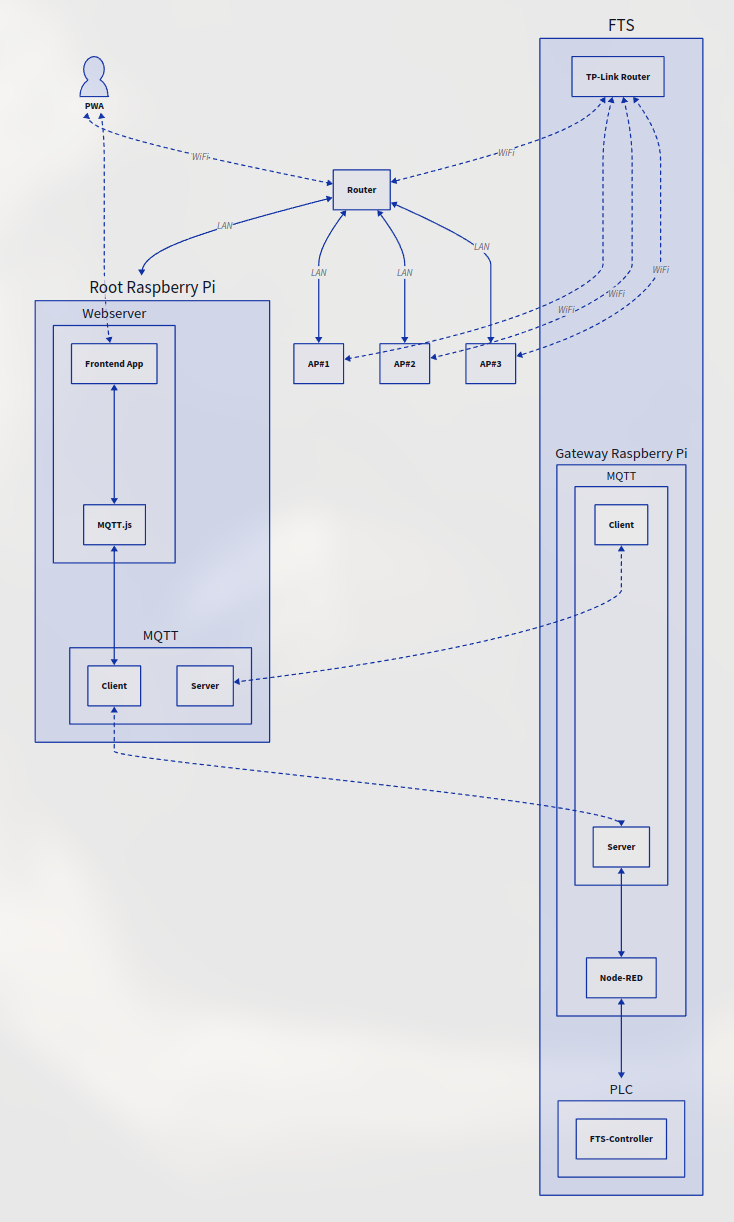

Overall system architecture showing frontend, backend and AGV communication

Overall system architecture showing frontend, backend and AGV communication

Technical specifications and integration points

Technical specifications and integration points

The project was driven heavily by technology choices focused on reliability and real-time performance. Here’s a look under the hood:

- Frontend: A mobile-first web application using SvelteKit

- Backend: Node.js handling authentication, data storage and real-time event processing

- Communication: Real-time updates via MQTT protocol and WebSockets to ensure that every movement, status and error of the AGVs was tracked live for fast, reliable state management

- Deployment: Hosted locally

This setup allowed the system to scale flexibly and stay highly responsive, both key factors when working with autonomous vehicles.

Designing for the User

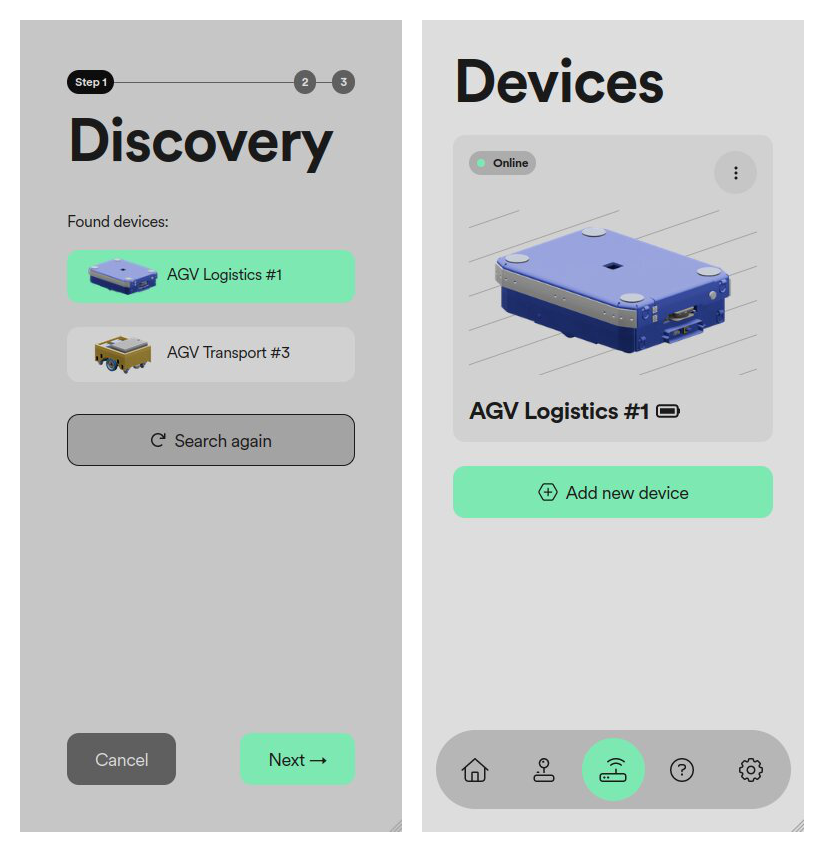

Just as important as the technology was the user experience. Many AGV systems overload users with complex controls and technical jargon. I wanted something different: a clean, intuitive interface that anyone could understand within minutes.

Interface Development

High-fidelity mockup of the control interface

High-fidelity mockup of the control interface

Responsive design on tablet device

Responsive design on tablet device

Key features of the UI included:

- A live map showing real-time positions of all AGVs

- A dashboard summarizing system status, battery levels and active tasks

- A manual control panel to issue direct commands (start, stop, navigate)

- Error and notification systems for quick troubleshooting

- Responsive design so operators could use tablets, desktops or industrial terminals interchangeably

Wireframes, mockups and early prototypes were tested with users from the workshop to ensure the design was truly user-centered, not just technically complete.

Challenges Along the Way

Building a system like this wasn’t without its hurdles. One of the biggest challenges was maintaining reliable real-time communication between the software and the AGVs. Packet loss, lag and unexpected disconnects were real issues, especially in busy network environments. Robust error handling and auto-recovery features became essential parts of the system architecture.

Another challenge was making sure the system could still operate even under suboptimal conditions, for example allowing local control if cloud services were unavailable.

Real-World Deployment

Exhibition and Presentation

Final project exhibition showcasing the complete system

Final project exhibition showcasing the complete system

Interactive demonstration for visitors and faculty

Interactive demonstration for visitors and faculty

Perhaps the most rewarding part of the project is this: Today, the system is actively used by customers managing their AGV fleets. It helps streamline material flows in production, reduces downtime and simplifies maintenance operations.

Seeing it move from a thesis project to a production tool showed me that academic work doesn’t have to stay theoretical. With the right focus, it can make a real-world difference.

What I Learned

This project taught me that bridging design and technology is a powerful combination. It also taught me that real-world projects are messy. They require resilience, adaptability and a strong focus on user needs, not just technical performance.

Most importantly, it launched me into the professional world of IoT and web development, fields I continue to be passionate about today.

Closing Thoughts

Looking back, this project was more than a thesis — it was a real introduction to building useful, reliable systems for real people. And it confirmed one thing for me: good ideas are great, but making them work in the real world is what really matters.